Corrugated sheets are often used in the garden as a cheap roof. They are easy to clean, break-proof, UV-resistant and can also be laid very easily by yourself.

Carports, garden houses, greenhouses or wooden shelters – corrugated sheets are often used here as roof coverings. The plates have several advantages.

They are very durable, can be cleaned quickly and can be laid by the hobby gardener with a little bit of craftsmanship alone. They are therefore the optimal and cheaper alternative to roof tiles and the like.

Various materials

Before you start laying the floor, you should familiarise yourself with the different materials. There are serious differences here. The experts from W&S Kunststoffe point out in a short material overview that although some materials are visually very similar, there are strong differences in the material. Be sure to look, see link above. It is important here that you find the right panels for you, which also meet your requirements.

Corrugated sheets can be found, for example, in the following materials:

- PVC

- GFK (glass fibre plastic)

- polycarbonate

- acrylic glass

Today, corrugated sheets made of polycarbonate or acrylic glass (Plexiglas) are most frequently used. Acrylic glass has a similar appearance as glass, but acrylic glass is much more robust. Polycarbonate is more similar to plastic, but is lighter and thinner than acrylic and also offers consistent impact strength. What you ultimately decide on is purely a matter of taste.

Laying corrugated sheets – how it works

Once you have decided on a particular material, you can get started. The construction is the same for all corrugated sheets.

The most important thing with corrugated sheets is a proper substructure. It looks like this:

For corrugated sheets, you need a substructure with transverse battens, on which you screw the sheets. This substructure can be made of metal or wood. With wood, however, you should make sure that it is not distorted. The most suitable glue-laminated beams are those that do not warp under the various weather conditions. Contrary to normal construction timber – in the worst case it can happen that damage (cracks) occurs to the panels. Especially with acrylic sheets you should be careful here, because they are very sensitive like glass.

The battens are fixed at right angles to the slope. The support distances vary depending on the material.

PVC and polyester

For PVC and polyester, use a support distance of 50 cm.

Polycarbonate and Arcyl

For polycarbonate and acrylic a distance of approx. 80 cm is sufficient.

These values apply to average snow and wind loads. If you have to expect higher loads, you should reduce the distance accordingly.

The last point that should be taken into account in the substructure is the top side. These should be painted lightly to prevent burns to the corrugated sheet. High temperatures prevail between the construction and the panel in summer, which can cause severe damage to PVC and GRP panels in particular. Here, the plates not only change their colour, but also deform.

➜ Screws

So that you can fasten the corrugated sheets to the substructure, you still need screws. The experts at Primo Befestigungstechnik recommend so-called tinsmith screws (available here) for this application. These are particularly watertight due to the sealing disc included. They are also weather and corrosion resistant. Optimal conditions for the use for the connection of plastic and wood.

➜ Saw

To be able to cut the corrugated sheets to your size, you also need a high-speed hand or table saw. Preferably with a fine-toothed saw blade equipped with carbide cutting edges.

➜ Drill

Also in stock you should have a conical drill (like this one) to pre-drill holes in the corrugated plates. By the way, these should be 3-4 mm larger than the diameter of the tin screws. This allows the plates to expand or shrink sufficiently in the event of temperature differences.

After you have made all the preparations and the tool is ready, you are ready to start laying. Proceed as follows:

✜ Step 1:

Start with the first corrugated sheet. Place it on the substructure and align it. Now the second plate follows. It is important that you work exactly with these two plates, then not much can go wrong with the following ones.

“By the way: Always work against the wind. This prevents water from pressing under the overlap in heavy rain.

✜ Step 2:

Fasten the first two corrugated plates with a few screws so that they cannot move.

“Caution: If you are moving back and forth on the corrugated sheets, you should always place a plank underneath to distribute the weight.

✜ Step 3:

After the first plates are fixed, you can continue with the other plates. Fix them with a few screws as well. At the end of the roof you should make sure that the ends are flush. Cut the plates accordingly in advance.

“Note: Drill the holes only on the wave crest.

✜ Step 4:

After all plates have been laid and fixed, you can carry out the remaining screwing. Experts recommend approx. 6 to 8 screws per square meter.

That’s it. And it wasn’t hard at all, was it?

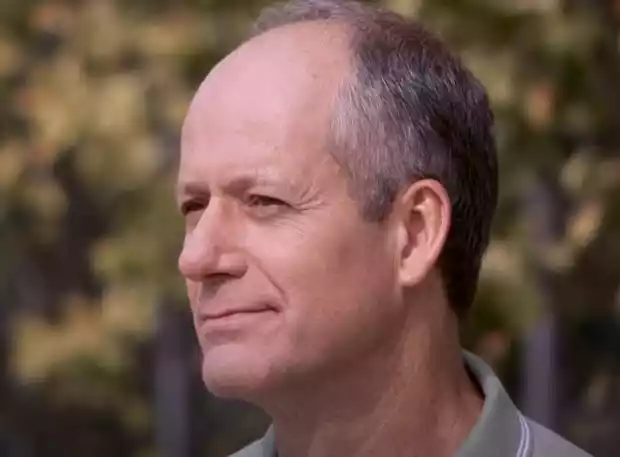

I am Don Burke, one of the authors at My Garden Guide. I am a horticulturist that cultivates, grows, and cares for plants, ranging from shrubs and fruits to flowers. I do it in my own garden and in my nursery. I show you how to take care of your garden and how to perform garden landscaping in an easy way, step by step.I am originally from Sydney and I wrote in local magazines. Later on, I have decided, more than two decades ago, to create my own blog. My area of specialization is related to orchid care, succulent care, and the study of the substrate and the soil. Therefore, you will see many articles dedicated to these disciplines. I also provide advice about how to improve the landscape design of your garden.